BrickBot

ME 2011 Final project | University of Minnesota | Fall 2014

|

As a new mechanical engineering student, I took a class called "Introduction to Engineering" that taught us all about engineering basics: CAD design, making drawings, schematics, project planning, ethics, and all other essential tenets of being a well rounded engineer.

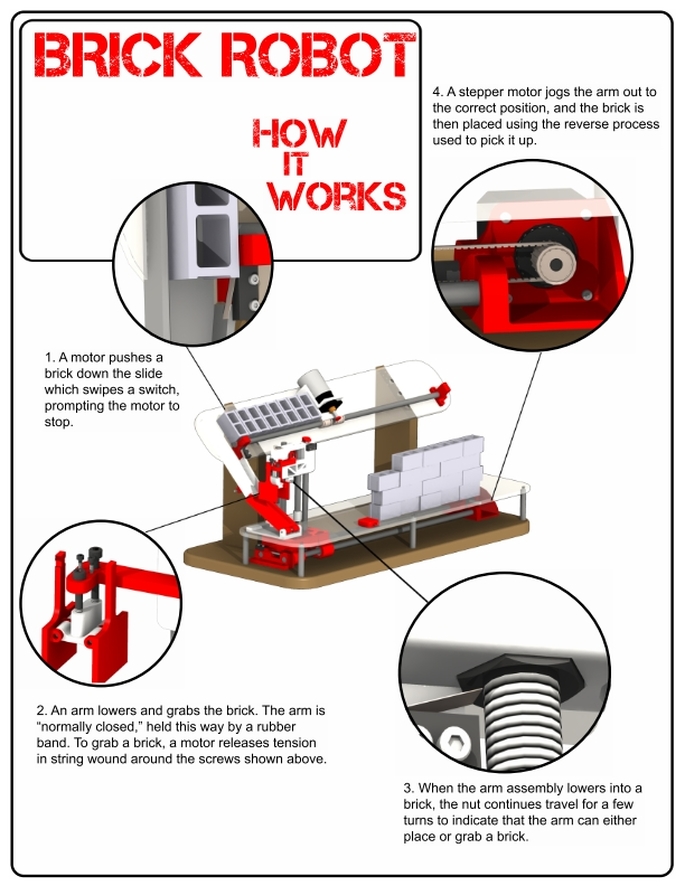

For our final project, we were given a $50 budget besides the basic materials provided: an arduino, 12v battery, several small motors, and miscellaneous relays and transistors. The goal of the project was to make a robot that did something for about a minute. That was all. I saw this post about a guy making miniature cinder blocks and got the idea for a robot that would cut the bricks out of extruded clay and stack them into a wall. After a week of toying around with the extrusion process, I decided to just make the bricks ahead of time and stack them in a wall. I built the robot over the course of about 5 weeks, finishing about a week before the robot show on December 8th. This show had every new Mech. E. student in a hall presenting their robots for both the public and teams of judges that walked around and scored them. I make an appearance about ten pictures down in this album which documents the show. In the end I was picked a "favorite" and received perfect scores from all of the judges who scored me. This earned me well over 100% on the project, all at the cost of a nearly sleepless November. DesignMy initial idea was for a robot that turned chess pieces out of clay or foam. I got through a few stages of prototyping before I realized that there wasn't a material clean enough to meet the show's requirements. By the time I had given this idea up, the show was just over a month away. Once I fully grasped the urgency of the situation I sat down and designed the whole thing in IronCAD over the course of a single 13 hour Sunday.

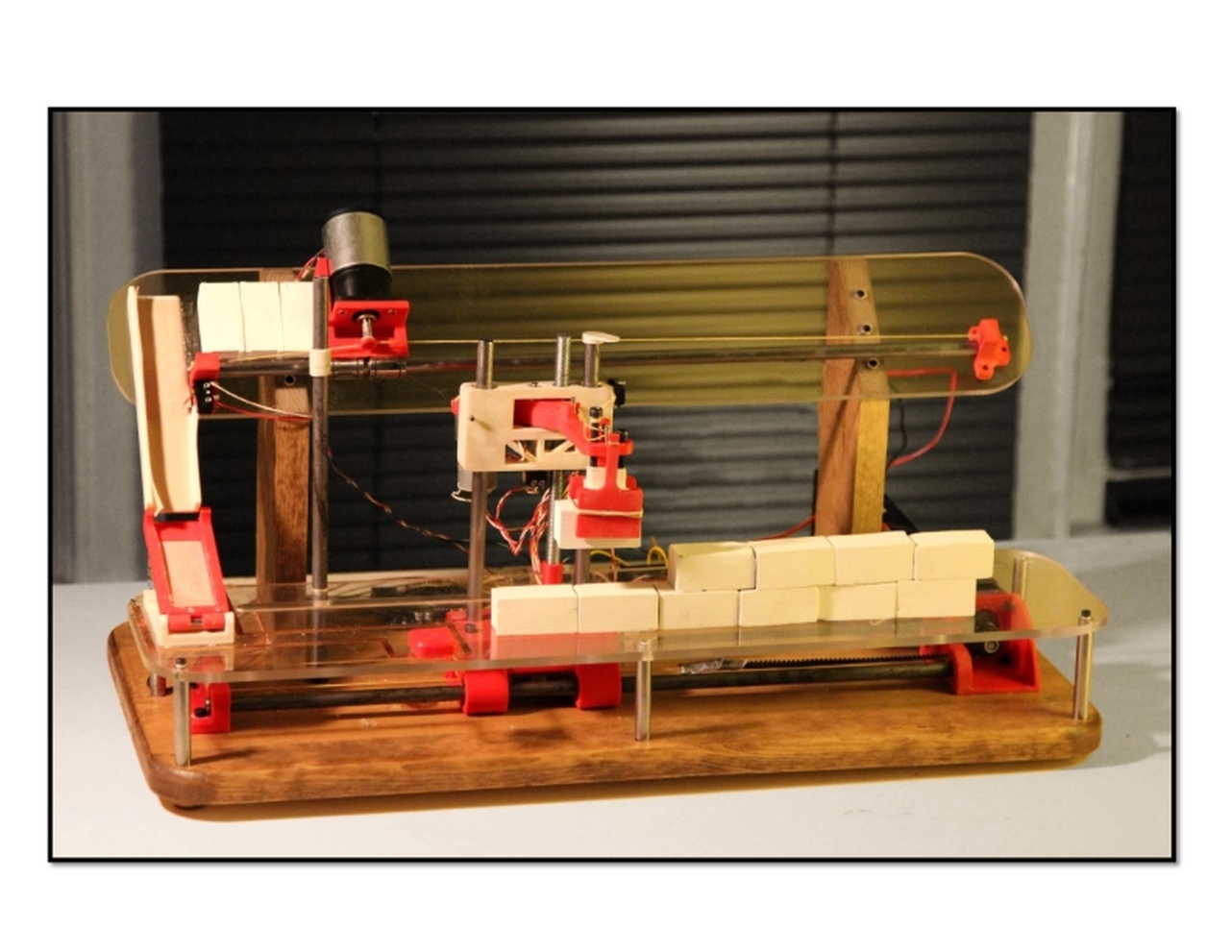

I focused the design around the fact that only the value of the raw materials needed to go towards the budget. This meant a lot of printed parts and a lot of scrap wood. I also didn't have enough in my budget for another motor and accompanying electronics, so the turning action of the arm was accomplished by a cam. In the end it was one parrot or circus clown away from the Rube Goldberg museum, but fit the prompt perfectly. MaterialsThrough the process of sourcing cheap materials for this project I got very lucky. I found a guy on craigslist who gave me a huge piece of clear acrylic for $5 because it had a good number of scratches (that I was mostly able to avoid.) The other component I stumbled upon was the linear bearings, which a co-worker was keeping in his desk because they were rusty and were going to be thrown out. I soaked and scrubbed them for a long time and in the end they were...usable.

The other materials were cheap but lots of work went in to making them as they appeared on the machine. Pictured below, the "straight hardened shafts" used throughout were actually the junk steel rods that are a few bucks each at Home Depot. I put each rod in the drill press and wet sanded them all down from 80 grit to a smooth 1500. I knew they would rust out eventually, but at least for the show it looked like I had actual chromed shafts. |

Check out the code and wiring schematic here. |